How To Optimize Thermal Conductivity with DVS Heat Transfer Systems in Extreme Environments

Innovations in Heat Transfer Equipments: What You Need to Know for Ideal Performance

Technologies in Heat transfer systems are changing efficiency across numerous markets. Advanced products like graphene and nanofluids assure significant improvements in thermal conductivity. At the same time, the integration of IoT and machine understanding offers chances for real-time tracking and enhanced energy performance. However, the landscape of thermal administration is rapidly progressing (DVS Heat Transfer Systems). Comprehending these advancements is necessary for attaining perfect system performance and sustainability in the future. What details innovations are shaping this transformation?

Arising Products for Enhanced Heat Transfer

Advanced Heat Exchanger Layouts

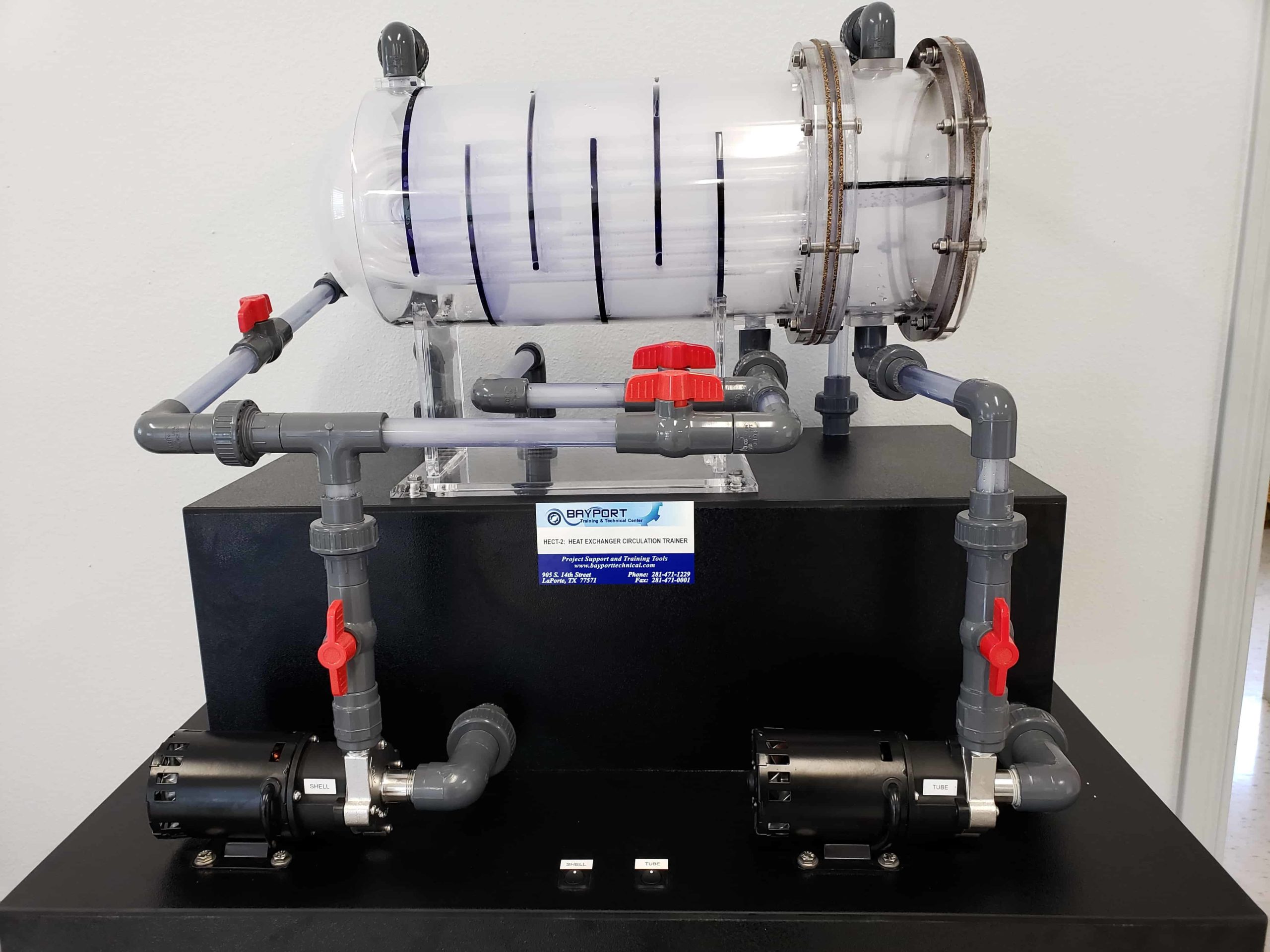

While typical Heat exchangers have served their function in various applications, advanced layouts are currently arising to meet the increasing needs for performance and efficiency. These innovative styles, such as plate, shell-and-tube, and finned-tube Heat exchangers, include enhanced surface locations and enhanced flow patterns to increase thermal transfer rates. Additionally, small layouts enable minimized room requirements without endangering effectiveness. Advanced products, such as compounds and corrosion-resistant alloys, additionally enhance toughness and efficiency under severe conditions. Additionally, simulation innovations and computational liquid characteristics are increasingly employed to improve these designs, guaranteeing peak Heat transfer attributes. As markets look for to minimize power intake and maximize outcome, the fostering of sophisticated Heat exchanger styles is critical in accomplishing these objectives.

The Duty of Nanotechnology in Heat Transfer

Nanotechnology plays an important function in boosting thermal conductivity within Heat transfer systems. By controling products at the nanoscale, scientists have accomplished substantial renovations in energy performance. These advancements not just optimize efficiency but also contribute to even more lasting power remedies.

Boosted Thermal Conductivity

Substantial developments in thermal conductivity have arised with the application of nanotechnology, changing Heat transfer systems across numerous markets. By including nanoparticles right into Heat transfer liquids and materials, researchers have accomplished remarkable boosts in thermal conductivity. These nanoparticles, such as carbon nanotubes, graphene, and metal oxides, boost the Heat transfer residential properties as a result of their high surface area and special thermal characteristics. The resulting compounds show boosted efficiency in applications varying from electronics cooling down systems to renewable resource modern technologies. Moreover, the capability to tailor the dimension, shape, and make-up of nanoparticles enables enhanced thermal administration solutions. Consequently, nanotechnology continues to play a crucial role in the development of more reliable and reliable Heat transfer systems, leading the way for enhanced commercial applications.

Power Efficiency Improvements

Combination of IoT in Heat Transfer Solutions

The combination of IoT in Heat transfer systems introduces the application of clever sensors that improve operational performance. These sensors allow real-time information surveillance, enabling prompt modifications and optimizations. This technical development has the possible to substantially improve performance and power administration in Heat transfer applications.

Smart Sensors Application

As Heat transfer systems evolve, the combination of smart sensing units through the Web of Points (IoT) has actually arised as a transformative technique. These sensors enable real-time surveillance of pressure, temperature level, and circulation prices, boosting system performance and integrity. By gathering and sending information, they promote positive upkeep, reducing the danger of system failures. Additionally, wise sensing units add to energy savings by refining operational parameters based upon site link environmental conditions. Their ability to examine abnormalities and fads enables for informed decision-making, ensuring peak performance of Heat transfer systems. As markets increasingly adopt this innovation, the execution of wise sensors stands to change just how Heat transfer systems are handled, leading the method for better sustainability and enhanced efficiency end results.

Real-Time Data Surveillance

Exactly how can real-time information keeping track of improve the effectiveness of Heat transfer systems? By integrating Web of Points (IoT) innovation, Heat transfer systems can leverage continuous information collection from clever sensing units. This real-time tracking permits for prompt evaluation of temperature, flow, and pressure rates, allowing drivers to determine ineffectiveness immediately. Subsequently, adjustments can be made to maximize performance, minimize power consumption, and expand tools life expectancy. Furthermore, anticipating upkeep can be applied, minimizing unexpected downtime and costly fixings. The capability to envision performance metrics via dashboards improves decision-making, cultivating an aggressive strategy to system management. Eventually, real-time information keeping track of not only boosts operational effectiveness yet additionally contributes to sustainability objectives within commercial procedures.

Energy Effectiveness and Sustainability Trends

Power performance and sustainability trends are reshaping the landscape of Heat transfer systems, driving development and compliance throughout numerous industries. Organizations are increasingly prioritizing energy-efficient styles to reduce functional prices and decrease environmental influences. The integration of renewable energy resources is ending up being much more widespread, enabling Heat transfer systems to operate sustainably while meeting regulatory demands. In addition, developments in technologies and products advertise reduced power consumption and enhance general performance. Lifecycle evaluations are additionally getting grip, permitting firms to assess the environmental effect of Heat transfer systems from production to disposal. This concentrate on sustainability not just sustains business responsibility however also settings companies competitively in a market where consumers increasingly prefer environmentally friendly solutions. Subsequently, power effectiveness and sustainability stay critical factors to consider for future advancements in Heat transfer innovation.

Technologies in Thermal Administration Solutions

While the need for efficient Heat transfer remains to climb, advancements in thermal management options are emerging to resolve both performance and sustainability difficulties. Advanced materials, such as stage change materials and nanofluids, are being established to enhance Heat transfer efficiency - DVS Heat Transfer Systems. These products boost thermal conductivity and enable better temperature level guideline in different applications. Additionally, modern technologies like active thermal control systems are gaining grip, making it possible for real-time changes to manage Heat circulation successfully. These systems contribute to energy savings and reduce the ecological impact of thermal processes. The integration of IoT in thermal administration helps with tracking and predictive maintenance, making certain maximized efficiency and longevity of Heat transfer systems. On the whole, these advancements represent substantial strides toward even more sustainable thermal administration practices

Future Directions in Heat Transfer Technology

Emerging advancements in thermal administration solutions signal an appealing future for Heat transfer technology. Scientists are progressively focusing on establishing products with exceptional thermal conductivity and improved power performance. Technologies such as nanofluids, which contain suspended nanoparticles, offer substantial improvements in Heat transfer efficiency. Furthermore, the integration of clever materials that adapt to varying temperature level problems is obtaining grip, enabling even more reliable and responsive systems. The surge of additive manufacturing techniques is additionally making it possible for the style of complicated Heat exchanger geometries that enhance liquid flow. In addition, the execution of artificial intelligence formulas is prepared for to reinvent the optimization of Heat transfer systems, promoting anticipating upkeep and performance enhancement. Collectively, these innovations are positioned to change the landscape of Heat transfer technologies in various markets.

Frequently Asked Questions

Just how Do I Select the Right Heat Transfer System for My Application?

Picking the right Heat transfer system involves reviewing application demands, consisting of temperature ranges, fluid buildings, and effectiveness demands. Analyzing system kinds, maintenance considerations, and cost-effectiveness also plays a necessary function in making an informed decision.

What Are the Upkeep Demands for Advanced Heat Exchangers?

Maintenance requirements for advanced Heat exchangers normally consist of regular evaluations, keeping track of for leaks, additional hints cleansing of surface areas, and guaranteeing optimal flow rates. Sticking to maker guidelines guarantees effective procedure and lengthens the tools's life expectancy.

Exactly How Do Environmental Elements Affect Heat Transfer Efficiency?

Environmental factors considerably affect Heat transfer effectiveness. Variants in airflow, temperature level, and moisture influence thermal conductivity and convective Heat transfer, eventually impacting system performance and demanding consideration throughout the layout and procedure of great site Heat transfer systems.

What Safety And Security Specifications Apply to Heat Transfer Solutions?

Security standards for Heat transfer systems typically consist of guidelines from organizations such as ASME and ASTM. DVS Heat Transfer Systems. These requirements address materials, style, and functional practices to assure reliability, performance, and defense versus dangers in numerous applications

How Can I Fix Common Heat Transfer System Issues?

Repairing common Heat transfer system issues entails examining for leaks, making sure proper fluid flow, evaluating insulation honesty, and verifying temperature differentials. Recognizing these elements can assist keep system performance and avoid more difficulties.

Nanotechnology plays an essential function in enhancing thermal conductivity within Heat transfer systems. Significant improvements in thermal conductivity have emerged through the application of nanotechnology, changing Heat transfer systems throughout different sectors. Developments in thermal conductivity with nanotechnology have led the way for remarkable improvements in power efficiency within Heat transfer systems. Energy effectiveness and sustainability fads are improving the landscape of Heat transfer systems, driving innovation and compliance across different industries. The integration of IoT in thermal management facilitates tracking and anticipating upkeep, making sure enhanced performance and longevity of Heat transfer systems.